If economically justified boiler water blowdown can be used to heat process streams. Water lost through radiator and system vents.

Common Chemicals Used In Boiler Water Treatment Sensorex

Silica Hardness Removal Polymer For Steam Generators And Boiler Systems Kurita En

Silica Scale Mcgraw Hill Education Access Engineering

Distilled water was formerly the most common form of purified water but in recent years water is more frequently purified by other processes including capacitive deionization reverse osmosis carbon filtering microfiltration ultrafiltration ultraviolet oxidation.

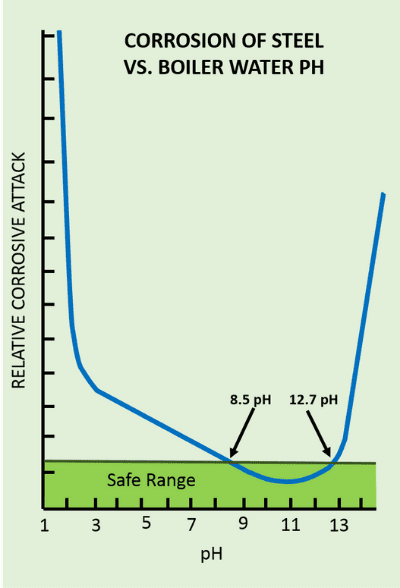

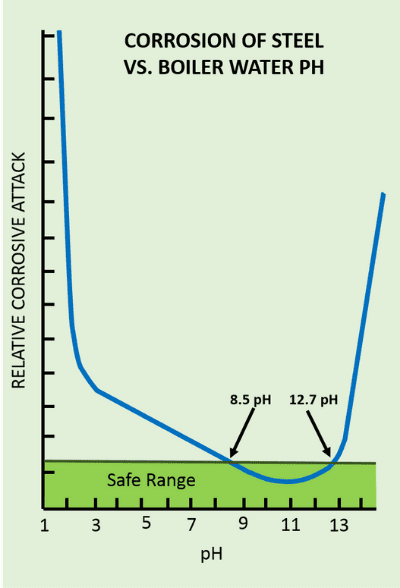

How to remove silica from boiler water. I am using R Pavlis water in my new machineSynchronika. Water having a low pH tends to be corrosive and may dissolve iron in objectionable quantities from pipe pumps and other equipment. Anion Bed Regeneration Anion resin in the form of hydroxyl is used to remove anions such as Chloride Cl Sulphate SO 4 Silica SiO 2 etc.

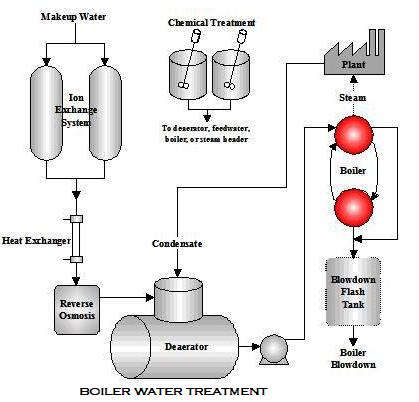

The regenerated resin is then put back into service. Chemical treatment of water inside the boiler is usually essential and complements external treatment by taking care of any impurities entering the boiler with the feed water hardness oxygen silica etc. The initial treatment of the water is important in addition to filtering monitoring water quality and adding chemicals as needed to maintain balance.

Clean Steam purity. The anion tank removes negatively charged ions sulfates chlorides carbonates bicarbonates nitrates and silica. Another set of chemicals is used specifically to remove copper in.

Extremely common iron Fe is dissolved from practically all rocks and soils. Boilers rely on the water to protect the steel boiler tubes from the temperatures in the furnace which greatly exceed the melting point of the tube material. The studs are coated with a refractory material usually silica or aluminium based that allows the cyclone to operate at a high enough temperature to keep the slag in a molten state and allow removal.

The combustion test was carried out continuously over ten months and ash deposits were sampled from various locations in the boiler. Feed-water purity is a matter both of quantity of impurities and nature of impurities. The deposits also concentrate any boiler water chemistry and.

An increased number of mud drum blows should be performed to remove the particles from the boiler. From the process water. High-Pressure Boiler Water Treatment.

Do not remove the coupons to look at them except at the end of the test period. These contaminants may include dissolved solids suspended solids and organic material such as iron copper silica calcium magnesium aluminum hardness and dissolved gases. I also drain a few ounces of hot water from the steam boiler to warm the cup daily.

Steam from a conventional boiler often called utility or plant steam is. If insufficient boiler water alkalinity is being maintained. Strong base anion units typically produce 02 megohm water at a pH of 8-9 whereas weak base anion units produce lower water quality a pH of 6-7 and do not remove silica or CO2.

Remove the bulk of dissolved solids and any hardness and silica. In this paper we for the first time report the properties of ash deposits collected from the combustion of lignite mixed with silica additive in a 30 MW th pulverised-fuel boiler with sub-critical steam conditions. Resin to recharge it with hydrogen ions and remove the cations which have been extracted from the sample water.

This can be done by making sure that the steam and boiler water are monitored on a regular basis. If silica is not present the magnesium will precipitate as magnesium hydroxide. The Importance of Boiler Water Treatment.

Boiler feed water treatment systems are used to protect boiler unit components and piping from damage due to certain contaminants present in the boiler andor makeup feeds. Inside the cyclone barrel are short densely spaced pin studs welded to the outside of the tubes. Boiler water treatment can prevent many issues with the system ranging from minor to severe.

Some impurities such as hardness iron and silica are of more concern for example than sodium salts. The blowdown from the flash tank is passed through an exchanger and used to preheat boiler makeup water. The wetness of the.

This reduces turbulence that can adversely affect the corrosion rate. Install soot-blowers to remove boiler tube deposits that reduce heat transfer between the hot combustion gas and the water. In many cases external treatment of the water supply is not necessary and the water can be treated only by internal methods.

Spotting as a result of steam impurities can be avoided by making sure that the steam quality is kept high. I use 4 grams of potassium bicarbonate in a gallon of distilled water as the R Pavlis water final formulation. A buildup of deposits inside the tubes will produce an insulating layer which inhibits the ability of the water to remove the heat from the tube.

What is the advice on ever needing to descale this new machine. The direction of water flow is important. If there is no feeder and boiler needs more water the red or yellow Low Water light will be illuminated on the low water cut-off located on side of boiler.

Water is essential to metal and mining operations but the industry is seldom the only consumer of water near extraction or processing sites. If an automatic water feeder is installed this device should add enough water on its own for boiler to operate. Mixed-bed deionized water systems.

Purified water is water that has been mechanically filtered or processed to remove impurities and make it suitable for use. Water should flow from the unattached end of the coupon toward the attachment end of the coupon. Inadequate maintenance of the boiler can cause boiler chemicals to.

To remove dissolved solids in boiler water Intermittent blowdown to remove suspended solids in boiler water Blowdown - Removes boiler water with a high concentration of solids which is replaced by feedwater containing a low concentration of solids WATER AND SOLIDS Basic Boiler Principles. When boiler water pH is not within the proper range calcium reacts with phosphate to form harmful calcium phosphate scale. The amount of energy used in the process to remove water is about half of what it would take to evaporate the.

The measurement of alkalinity of water is necessary to determine the amount of lime and soda needed for water softening eg for corrosion control in conditioning the boiler feed water. Injection into high purity water for heating prior to Clean-in-Place CIP operations. The cyclone barrel is constructed with water cooled tangential oriented tube construction.

Alkalinity of water is mainly caused by the presence of hydroxide ions OH bicarbonate ions HCO 3 and carbonate ions CO 3 2 or a mixture of two of these ions in water. The purity requirements for any feed-water depend on how much feed water is used as well as what the particular boiler design pressure heat transfer rate. Wait at least 15 minutes.

In most cases boiler water blowdown heat recovery systems use flash steam from the flash tank for deaeration. WaterSense is an EPA national voluntary partnership program that offers a simple way for consumers to identify water-efficient products homes and services. Groundwater generally contains more silica than surface water.

Other impurities such as silica and iron can be tied up by dispersants and chelants and remain suspended in the boiler water where they can be removed by continuous surface or bottom blow down. By monitoring and treating source water mining companies not only ensure their own quality standards are met but they also can contribute to the health of communities agricultural resources and wildlife ecosystems in the process. It is very effective at removing silica deposits from the.

Boiler Feedwater Treatment

Boiler Water Treatment Basic

Do Industrial Facilities Need To Remove Silica From Feed Water And Effluent

An Innovative Economical And Efficient Method Of Silica Removal From Waters Water Technology

Boiler Water Treatment Preventative Maintenance Chemready

Water Handbook Boiler Deposits Occurrence And Control Suez

Pdf Silica Removal During Lime Softening In Water Treatment Plant Semantic Scholar

Library E Abb Com